AODD Pumps

We are one of a leading AODD Pumps manufacturers in Mumbai India. We have a compleate range of AODD Pumps in compare to material and size. Our range of AODD Pumps include PP AODD Pumps, PVDF AODD Pumps, SS AODD Pumps, Aluminium Pumps. Thinking of AODD Pumps we have all sizes from 0.5” to 3”.

What are diaphragm pumps used for?

A diaphragm pump is a positive displacement pump that employs a combination of reciprocating motion and either a flapper valve or a ball valve to transfer liquids. It can be hydraulically or mechanically activated.

The short name of this pump is AODD Pump and this AODD Pumps are used where a multiple Liquide type and viscosity has to be operated by single pump. AODD Pumps are easy to carry and are Self-priming pumps and are good for thick liquids. Diaphragm pumps are used in almost every significant industry. They’re frequently used to transport abrasive fluids like concrete, as well as acids and chemicals. They’re also widespread in cars and aeroplanes. A membrane pump, air operated double diaphragm pump (AODD), or pneumatic diaphragm pump is a type of diaphragm pump.

AODD (Air-Operated Double-Diaphragm) Pumps are leakage-resistant pumps that are used to handle highly corrosive chemicals, sludges or viscous fluids. AODD pumps feature two flexible membranes or diaphragms anchored on a common shaft. The forward and backward movement of these diaphragms cause the movement of fluids as desired. Instead of controlling the diaphragm by means of a motor, AODD pumps make use of compressed air, by alternately directing air to either of two air chambers on the diaphragms.

How does a AODD Pump Work?

An AODD pump is a type of positive displacement pump that is driven by compressed air. A coupled shaft transfers the compressed air from one chamber to the other, allowing the chambers to move at the same time. This back-and-forth action drives liquid from one chamber into the discharge pipe while filling the other chamber with liquid at the same time.

When compressed air is connected to an AODD pump, it enters an air motor, which directs the air to push a diaphragm, ‘pushing the liquid out.’ The pushed diaphragm is connected to a shaft, which pulls the opposite diaphragm, creating a cavity on the other side and drawing in the liquid. One-way valves, usually a ball valve or a flap valve, are located at the bottom and top of the two cavities. When a cavity is closed, the liquid is pushed up and out, whereas when a cavity is opened, the liquid is sucked in. This will then alternate between closing the cavity on one side and opening the cavity on the other. This can all happen at speeds of up to 400 cycles per minute.

What are the main characteristics and advantages of an AODD pump?

AODD pumps are almost completely leak-free. Because there are only stationary seals between the wetted parts and the surrounding environment, leakage can occur only if one or both diaphragms fail. Diaphragms should be replaced on a regular basis as part of a general maintenance programme, according to the manufacturer’s recommendations. Because of the benefit of pressure balancing provided by the compressed air supply, diaphragms in an AODD pump wear less than those in a mechanically driven diaphragm pump.

AODD pumps can handle abrasive, highly viscous fluids, sludges, and slurries. Furthermore, because of the gentle pumping action, they are ideal for shear-sensitive fluids. The four internal check valves are typically designed with a ball (or cone)/seat or a flap. Ball valves offer a better seal and are less prone to wear than flap valves. Because flap-type valves are hinged, prolonged use causes fatigue at the flexing point. Because the ball is free to rotate during operation and settle in a different position on the seat, ball valves wear more evenly. Flap-type check valves have the advantage of being able to pass large solids entrained within the pumped fluid more easily.

An AODD pump can be run dry indefinitely because there are no internal seals or moving components that require lubrication or cooling. AODD pumps are self-priming, with some having a suction lift of up to 8m.

Because they are powered by compressed air rather than electricity, AODD pumps are suitable for use in hazardous areas. As long as the air vent is above the liquid level, an AODD pump can be safely submerged.

What is the purpose of Air Operated Double Diaphragm Pumps?

AODD pumps have a high suction lift, are self-priming in most fluids, and can run dry. These pumps can easily handle low to medium viscosity fluids (including those with large suspended solids) and can pump both corrosive and flammable liquids. In the processing industries, it is said that if a material can be poured into an AODD pump, these pumps can generally pump it.

AODD pumps are relatively inexpensive to purchase and operate due to their simple design, and when combined with their efficiency and accuracy, stainless steel versions are well suited for certain food grade sanitary processing applications such as filling, dispensing, and metering fluids, as well as water removal.

AODD Pumps testing facility

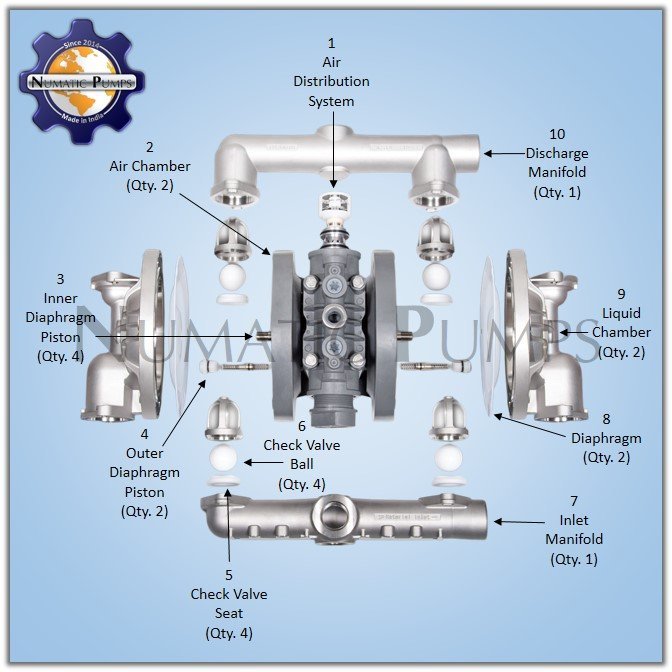

AODD Pumps spare part view

Pump Articles by Numatic Pumps

What is the purpose of Air Operated Double Diaphragm Pumps?

AODD pumps have a high suction lift, are self-priming in most fluids, and can run dry. These pumps can easily handle low to medium viscosity fluids (including those with large suspended solids) and can pump both corrosive and flammable liquids. In the processing industries, it is said that if a material can be poured into an AODD pump, these pumps can generally pump it.

AODD pumps are relatively inexpensive to purchase and operate due to their simple design, and when combined with their efficiency and accuracy, stainless steel versions are well suited for certain food grade sanitary processing applications such as filling, dispensing, and metering fluids, as well as water removal.

Diaphragm Pumps Market Research

The diaphragm pump market is estimated to grow at a CAGR of more than 6.1% between 2022 and 2025. The COVID-19 pandemic has had a detrimental influence on the growth of the air operated diaphragm pump industry, as the industrial sector saw a major drop in demand for AODD Pumps during the pandemic, resulting in lockdowns. During 2022 and 2023, smaller firms and organizations with relatively poor financial positions were shut down, lowering overall industrial AODD Pumps manufacturing capacity and consolidating the consumer sectors. Furthermore, as demand for oil and gas grows, oil prices recover, and an increasing number of onshore and offshore fields reach maturity, exploration and production activities are expected to shift to deeper offshore regions, increasing offshore ultra-deepwater projects. This, in turn, is likely to boost the market for double diaphragm pumps throughout the forecast period. However, technical developments in traditional pump alternatives, such as solar pumps, are projected to impede the diaphragm pump market throughout the projection period.

AODD pumps are air-powered displacement pumps that are distinct from all other positive-displacement pumps. While pumping, the diaphragm is balanced due to air pressure acting on the full surface of the diaphragm. This significantly increases diaphragm life over mechanically driven diaphragm pumps. Because compressed air is restricted, the pump’s maximum pressure is likewise safely limited. As a result, Air Operated Double Diaphragm pumps are ideal for an on-off cycle, on-demand intermittent, and continuous operation needs.

The AODD pump’s basic genius implies that there are just a few dynamic wetted parts: the two diaphragms joined by a common shaft, the two intake valve balls, and the two output valve balls. The diaphragms serve as a barrier between the compressed air source and the liquid. Driving the diaphragms with compressed air rather than the shaft balances the strain on the diaphragm, eliminating mechanical stress and extending diaphragm life. This also permits the valve balls on the valve seats to open and close, directing liquid flow. Because of its simple design and operation, it is simple for the operator to identify the proper pressures and flows to maximize its functioning.